Line Shaft Winch

Direct Winch

Zero Float Winch

Linear Winch Compact

Moveable Shaft Winch

Moveable Point Hoist

Intecon Control System

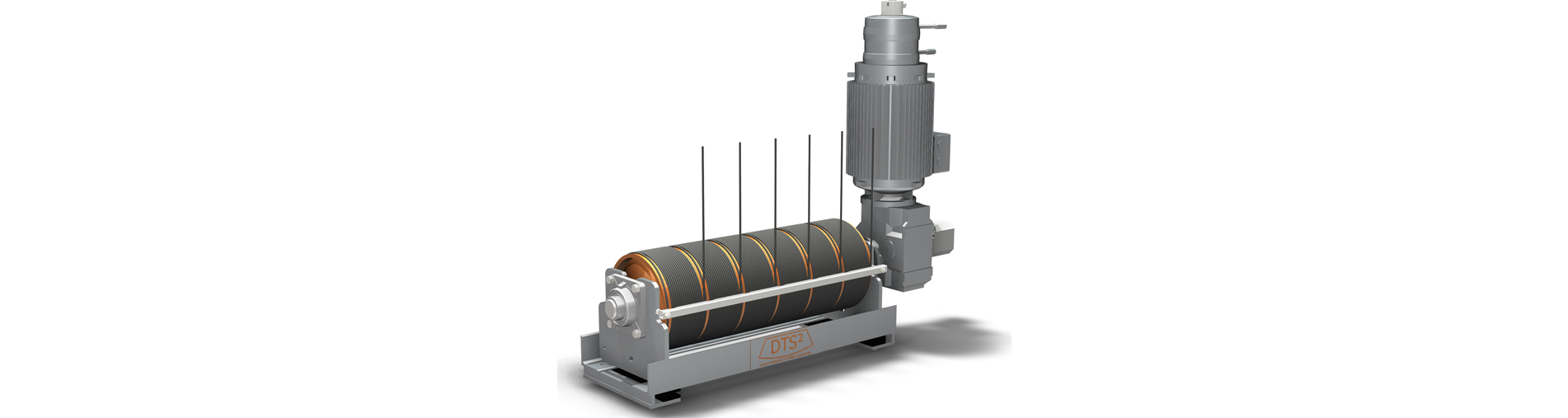

Line Shaft Winch

300kg capacity

Ideal for theatres that lack space for a hoist loft or engine room, the Line Shaft Winch (LSW) can be ceiling mounted while maintaining the standard working distance of 200mm between winches. Outstandingly reliable, the LSW provides excellent performance and a torsion-free drive.Separate cable drums are connected by drive shafts, with the motor to one side. The drive shafts up are precisely aligned to ensure virtually no torsion on the driveline, even with extreme point loads.

- Up to 1.2m per second

- BVG-C1 compliant

- Meets SIL-3 safety regulations

Advanced encoder and sensor options include:

- Speed and position

- Drive unit temperature monitor

- Brake monitor

- Slack cable detection

- Weight sensors.

Direct Winch

300kg – 600kg capacity

Unique, versatile and robust, the Direct Winch can be flexibly integrated into every application and in any theatre while meeting all applicable safety and performance demands. It requires sufficient space to compensate for the fleet angle of the outgoing steel cable.

- Horizontal drum and steel cables

- Up to 2m per second

- BVG-C1 compliant

- Meets SIL-3 safety regulations.

Advanced encoder and sensor options include:

- Speed and position

- Drive unit temperature monitor

- Brake monitor

- Slack cable detection

- Weight sensors.

Zero Float Winch

300kg – 500kg capacity

Where space is limited, opt for the Zero Float Winch which can be used either vertically or horizontally. Precise engineering ensures reliability, with low noise and vibration levels.The drum moves up and down the winch frame with the drive, while return wheels ensure the cables run in a straight line from the drum.

- Specify the control system of your choice

- Up to 1.8m per second

- BVG-C1 compliant

- Meets SIL-3 safety regulations.

Advanced encoder and sensor options include:

- Speed and position

- Drive unit temperature monitor

- Brake monitor

- Slack cable detection

- Weight sensors.

Linear Winch Compact

300kg capacity

Slick, compact and revolutionary, Linear Winch Compact is the smart little brother of the traditional Zero Float Winch and guarantees a first class performance. Measuring just 2100mm x 200mm x 700mm, it takes up no more space than a manual fly bar. One row of this winch provides for an entire fly bar gallery; incorporate the control system within the winch and save even more space!

- Up to 1.2m per second

- Sound proofed high grade plastic casing

- Acoustically separate from the building to reduce vibration levels

- 16m hoist height

- 6 connection points for truss or bar.

- BVG-C1 compliant when equipped with double brakes, overload detection and slack cable detection

- Meets SIL-3 safety regulations.

Moveable Shaft Winch

300kg capacity

With the Movable Shaft Winch, you install only as many winches as you need, making it an economical choice. Providing maximum flexibility, the MSW is a standard shaft winch which can travel freely to every position on the grid, with or without a load.

- Movable load

- 2m per minute travel

- Specify the control system of your choice

- BVG-C1 compliant when equipped with double brakes, overload detection and slack cable detection

- Meets SIL-3 safety regulations.

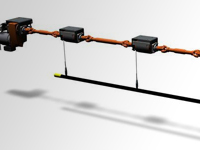

Moveable Point Hoist

150kg – 250kg capacity

The Moveable Point Hoist is a flexible system which enables each point hoist to be moved automatically along the ceiling guide profiles and so positioned wherever needed. When used with the Intercon control system, it provides for complete flexibility. It has been designed to allow for a random combination of hoist points – hoist fly bars on the skew or host multiple fly bars in formations such as straight line, triangle or square. Its design ensures the cable is always wound straight up and down.

- 2m per minute travel

- BVG-C1 compliant when equipped with double brakes, overload detection and slack cable detection

- Meets SIL-3 safety regulations

- 200mm minimum working distance.

Intecon Control System

For this high end control system, DTS2 partnered with German company BBH Systems GmbH, renowned for its safety, functionality and reliability:

- High speed programming of complex movements and scene changes

- Touch screen interface for complete and detailed overview of fly bar gallery

- Special function keys enable quick and easy complex programming functions

- Proven reliability

- Over 1000 axes automated each year

- Worldwide diagnostic back up direct from BBH technicians.